Facility

At our company, we pride ourselves on maintaining a state-of-the-art facility equipped with a comprehensive range of advanced mold processing equipment. Our cutting-edge machinery ensures precision, efficiency, and reliability at every stage of the mold manufacturing process. Below is an overview of our leading-edge equipment:

CNC:

We operate 15 high-precision CNC machining centers, including 3 FANUC machines and 2 MAKINO high-speed machines. These machines are capable of handling complex geometries and tight tolerances, ensuring the highest level of accuracy in mold production. Our largest CNC machine boasts an impressive stroke range of 3000*1600mm and can handle a maximum workload of 10 tons, making it ideal for large-scale and high-precision projects. With advanced automation features and multi-axis capabilities, our CNC machines deliver unmatched performance and consistency.

EDM:

Our EDM department is equipped with 8 advanced machines, including 2 double-headed EDM machines and 2 MAKINO machines featuring an automatic electrode changing system with 16 electrodes. These machines excel in producing intricate details and complex shapes that are difficult to achieve with traditional machining methods. The precision and versatility of our EDM equipment allow us to meet the most demanding requirements of mold manufacturing, ensuring superior surface finishes and dimensional accuracy.

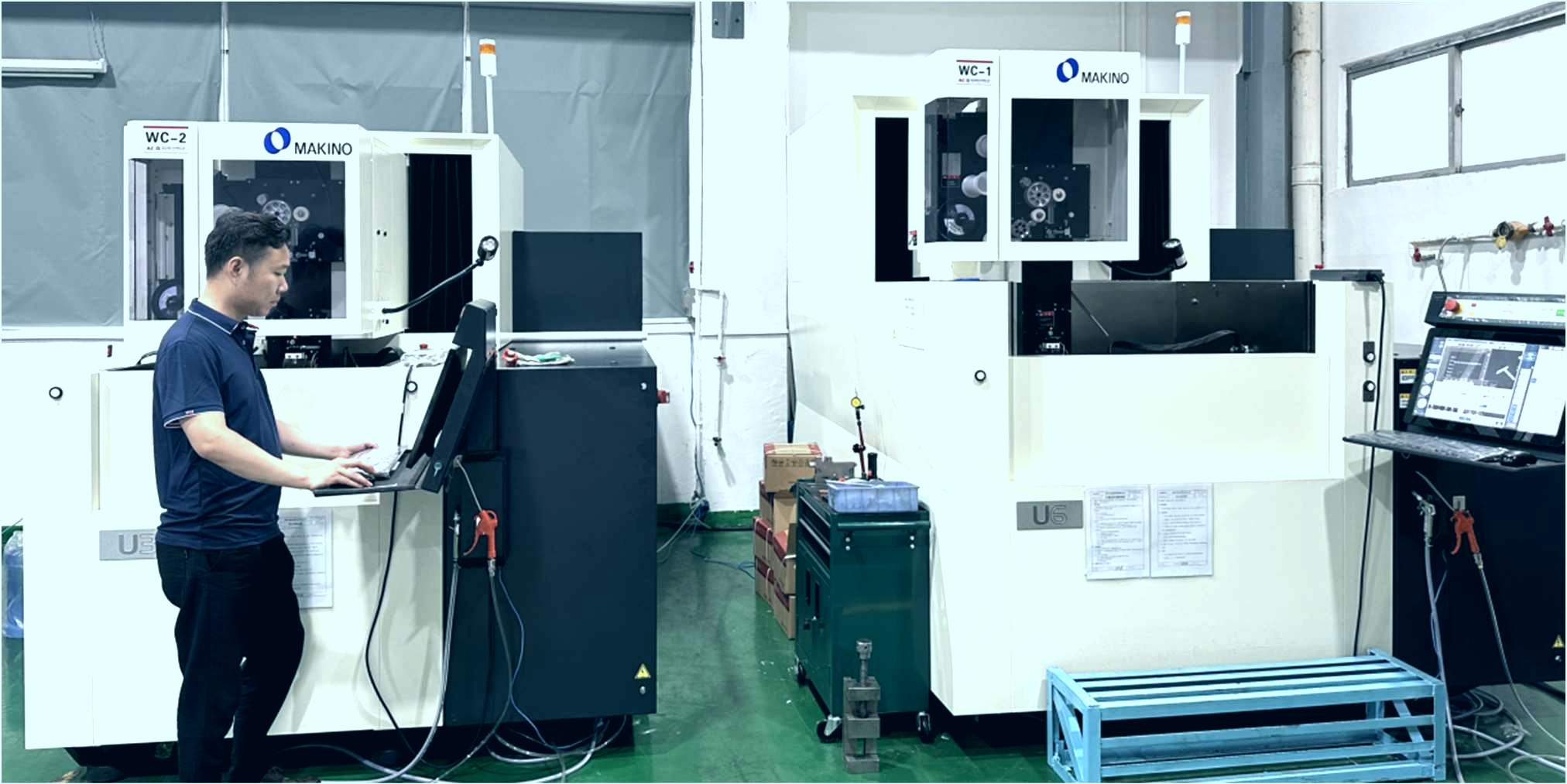

Wire Cut:

For precision wire cutting, we utilize 2 MAKINO high-precision wire cut machines. These machines offer a stroke range of 650*450mm and can handle a maximum workload of 1.5 tons. Known for their exceptional accuracy and repeatability, our wire cut machines are ideal for producing fine details and intricate contours in molds. The advanced technology behind these machines ensures minimal material waste and optimal efficiency, making them a critical component of our manufacturing process.

Mold Assembly

To complement our advanced machining capabilities, we have a dedicated mold assembly department equipped with 1 spotting machine and supported by 4 skilled assembly teams comprising 30 experienced mold makers. Our assembly teams specialize in mold fitting, fine-tuning, and final assembly, ensuring that every mold meets the highest standards of quality and functionality. The spotting machine plays a crucial role in verifying the alignment and fit of mold components, ensuring seamless operation and longevity of the finished product.

Specialty Tooling Capabilities

At ACG Mold, we specialize in providing highly complex and precision tooling solutions tailored to meet the unique demands of advanced manufacturing. Our expertise and state-of-the-art technology enable us to deliver innovative mold designs that push the boundaries of what’s possible. Below are some of our key specialty tooling capabilities:

High-Cavitation Molds

Stack Molds

Unscrew Molds

Insert Molds

over molds

In-Mold Closing

Gas injection molds

2k/3k molds

IML/IMD molds

MUD molds

Babyplas molds

Prototype molds