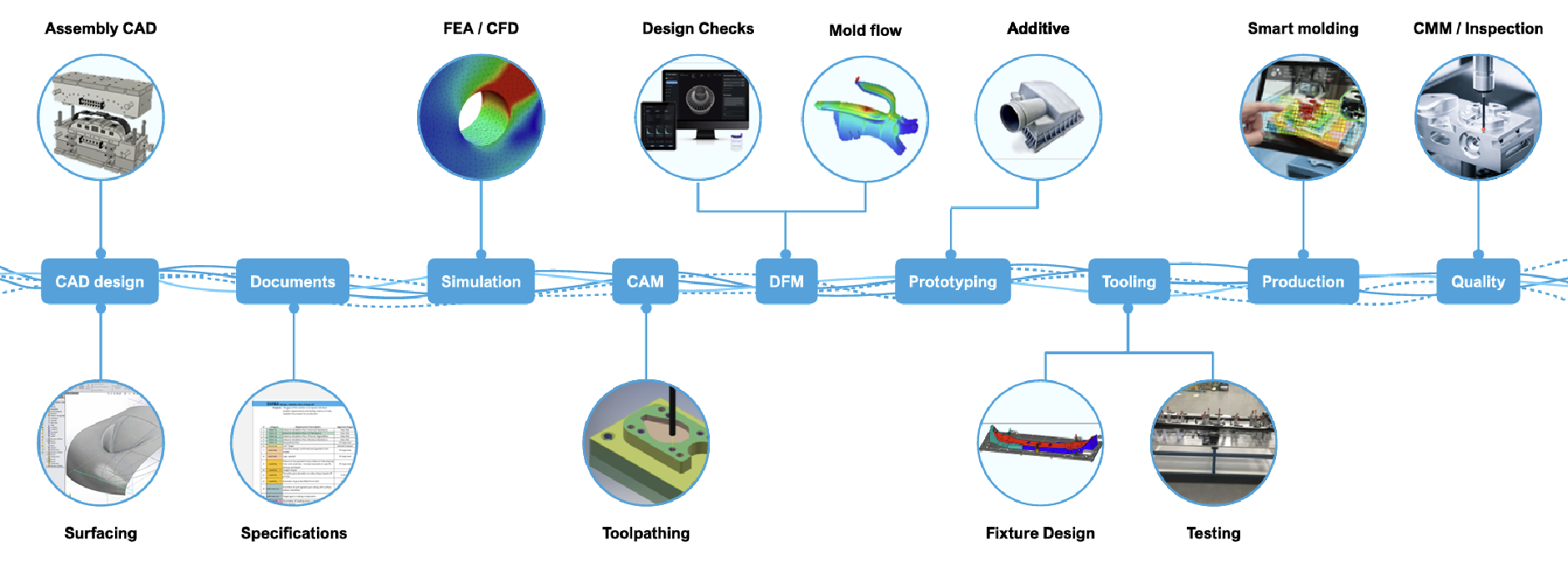

Continuous Data Connection Across The Product Lifecycle

Design for Manufacturability (DFM)

Optimize your part design to fabricate high-quality parts at the lowest possible cost per unit. By taking the manufacturing method and its restrictions into account, we reduce production time, cut costs and prevent excessive redesigns.

Our DFM checks vary by manufacturing process and include:

Aspect Ratio

Wall Thickness

Feature & Part Size

Process Resolution

Watertightness

Venting

Surface defect

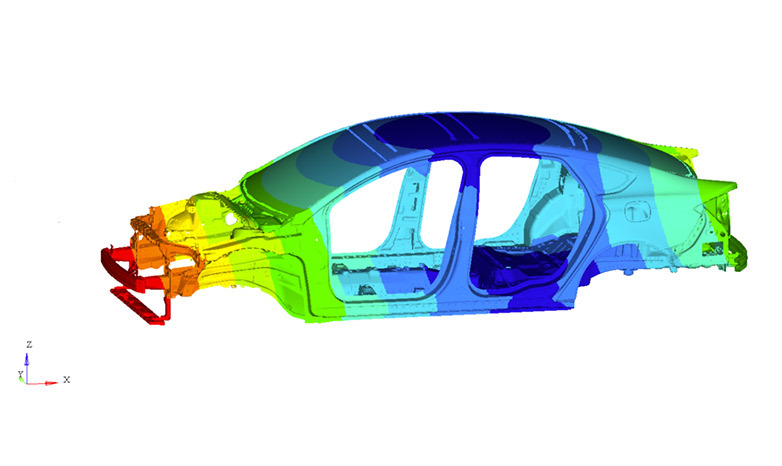

Simulation Analysis

By harnessing the power of advanced 3D software, ACG mold has the ability to perform Finite Element Analysis (FEA) and Computational Fluid Dynamics (CFD) to study the characteristics and in-use behavior of physical components and systems. These processes allow engineers to spot and resolve potential issues before ever creating a physical part, resulting in fewer design iterations and saving on overall production costs.

Our simulation analysis capabilities include:

Mold Flow Analysis

Thermal Analysis

Structural Analysis

Fluid Dynamic Modeling

这里是占位文字

这里是占位文字